Cold Rolling Mill

With the feature of good surface quality,good surface finish,high precision,excellent product property,etc.Cold Rolled strip is widely used for Continuous hot galvanizing line(CGL)

Category:

Keywords:

Cold Rolling Mill

With the feature of good surface quality,good surface finish,high precision,excellent product property,etc.Cold Rolled strip is widely used for Continuous hot galvanizing line(CGL),Color coating line(CCL),Automobile industry,household appliance industry,aircraft industry,instrument industry and food packaging,etc.With the development of economic,the demand of cold rolled strip is growing.

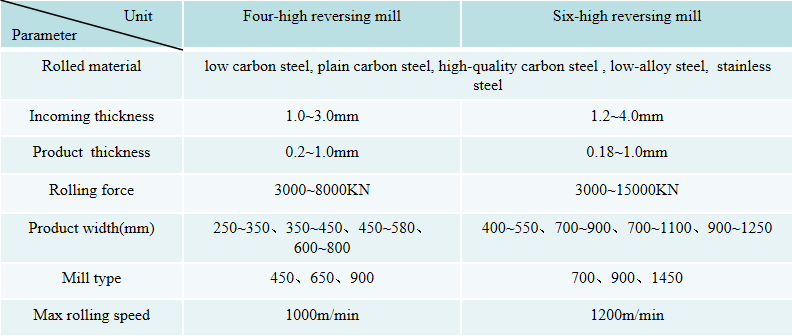

According to the feature of the product and customer requirement,we can design and produce four-high reversing mill,six-high reversing mill with the different specification.The product line has the characteristics of high technology reliability and high investment.

Four-high reversing mill

Characteristics of four high rolling mill:

1.Transmission Model:Work roll and backup roll drive.

2.Press-down Mode:Electric screw down and AGC hydraulic press down.3.The Four-high reversing mill has work roll bending system,adjust the work roll's convexity quickly,change the contact pressure distribution between the roll,achieve the purpose of control strip shape.4.The Four-high reversing mill has the features of simple structure,convenient to maintain and operation,small investment,etc.5.AGC Four-high reversing mill has the features of high control precision suitable for high-precision cold rolling strip production.

Production processing:

uncoiler(with the coil car)→leveler with telescopic guide table→entrance tension recoiler→coil stripping car→front equipment of the rolled mill→Four-high reversing mill→back equipment of the rolled mill→exit tension recoiler(coil stripping car)→belt wrapper.

Six-high reversing mill

Six-high reversing mill is used for pickling hot rolled strip,to meet customers'demand for different strip thickness.Unit is comprised of uncoiler,recoiler,Six-high reversing mill,lubricating system,hydraulic system and electric system,etc.

Characteristics of four high rolling mill:

1.Transmission Model:Work roll drive.

2.Press-down Mode:AGC hydraulic press down.It has the features of high control precision suitable,fast system response,high degree of automation.3.Bend Mode:WR(Working Roller)positive and negative bending,adjust the work roll's convexity quickly,change the contact pressure distribution between the roll,achieve the purpose of control strip shape.4.The unit is simple in structure,easy to the maintenance operation,small investment.

Production processing:

uncoiler(with the coil car)→straightening machine with strip guide unit→entrance tension recoiler→coil stripping car→front equipment of the rolled mill→Four-high reversing mill→back equipment of the rolled mill→exit tension recoiler(coil stripping car)→belt wrapper.

Previous page

Next page

Previous page

Continuous hot galvanizing line(CGL)

Next page

With the feature of good surface quality,good surface finish,high precision,excellent product property,etc.Cold Rolled strip is widely used for Continuous hot galvanizing line(CGL)

Continuous hot galvanizing line(CGL)

Continuous hot galvanizing line(CGL)continuous plate of zinc or aluminum zinc coating on the surface of cold-rolled steel plate,increase the corrosion resistance of steel plate

Color coating line(CCL)is to coat the strip surface with organic,make the surface more colorful and further enhance the corrosion resistance of strip

Pickling line plays a key role before cold rolling,Its main function is to use mechanical and chemical function,remove the strip iron and dirt of the strip steel surface after hot rolling