Color coating line

Color coating line(CCL)is to coat the strip surface with organic,make the surface more colorful and further enhance the corrosion resistance of strip

Category:

Keywords:

Color coating line

Color coating line(CCL)is to coat the strip surface with organic,make the surface more colorful and further enhance the corrosion resistance of strip,the main process is degreasing cleaning,painting and drying solidification,etc.

Production processing:

Coil car→Uncoiler→Pinch roll→Entry shear→Welding machine→Tension bridle→Entry loop→Tension bridle→Degrease machine set→Hot air dryer→Chemical roller coater→Hot air drying oven→Tension bridle→CPC unit→Primer coater→Primer coating curing oven→Air cooling→Water cooling→CPC unit→Finish coater→Finish coating oven→Air cooling→Water cooling→Hot air dryer→Tension bridle→Exit loop→Exit shear→Exit pinch roll→Recoiler→Coil stripping car.

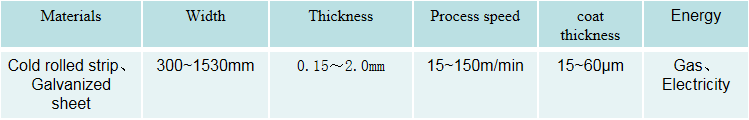

Technical parameter:

CCL technology:

Materials:Cold rolled strip,Galvanized sheet,Aluminum Strip.

Primer coating materials:Epoxy resin,polyester,Polyurethane.

Finish coating materials:polyester,Fluorocarbon,Silicon modified polyesters(SMP),Polyurethane.

Product type:Construction panel,Home electrical appliances,Multi-functional color plates,Decorative plates.

The line equipped with cold and hot laminator,which is adopted for the production of household electric appliance or steel plate for specific appliance.

Adopt catalytic burning for volatile solvent,which save energy consumption and avoid environmental pollution.

Previous page

Next page

Previous page

Picking line

Next page

With the feature of good surface quality,good surface finish,high precision,excellent product property,etc.Cold Rolled strip is widely used for Continuous hot galvanizing line(CGL)

Continuous hot galvanizing line(CGL)

Continuous hot galvanizing line(CGL)continuous plate of zinc or aluminum zinc coating on the surface of cold-rolled steel plate,increase the corrosion resistance of steel plate

Color coating line(CCL)is to coat the strip surface with organic,make the surface more colorful and further enhance the corrosion resistance of strip

Pickling line plays a key role before cold rolling,Its main function is to use mechanical and chemical function,remove the strip iron and dirt of the strip steel surface after hot rolling