Uncoiler and Recoiler

The uncoiler and coiler are indispensable components of various strip production lines.They are used for strip uncoiling and coiling respectively

Category:

Keywords:

Uncoiler and Recoiler

The uncoiler and coiler are indispensable components of various strip production lines.They are used for strip uncoiling and coiling respectively,and form uncoiling tension and coiling tension on the production line.According to different plate thickness and customer demand,our company can design and manufacture clamp coiler and seamless coiler.

1.Composition of equipment:

A)Unwinding main body:cantilever floating structure.It is composed of drum,reducer,motor,brake,base,cylinder,piping and so on.

B)Up and down coil trolley:composed of lifting saddle,lifting hydraulic cylinder,track,wheel,reducer motor(or hydraulic motor)track,movable guide plate,etc.

C)Auxiliary support:used for supporting the end of the drum,consisting of hydraulic cylinder,swing frame,end support,etc.

D)Coiler:It consists of belt,hydraulic cylinder,fixed bracket,movable bracket,tow chain,etc.

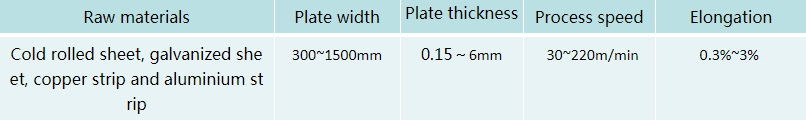

2.Equipment parameters:

Previous page

Next page

Previous page

Finishing machine

Next page

With the feature of good surface quality,good surface finish,high precision,excellent product property,etc.Cold Rolled strip is widely used for Continuous hot galvanizing line(CGL)

Continuous hot galvanizing line(CGL)

Continuous hot galvanizing line(CGL)continuous plate of zinc or aluminum zinc coating on the surface of cold-rolled steel plate,increase the corrosion resistance of steel plate

Color coating line(CCL)is to coat the strip surface with organic,make the surface more colorful and further enhance the corrosion resistance of strip

Pickling line plays a key role before cold rolling,Its main function is to use mechanical and chemical function,remove the strip iron and dirt of the strip steel surface after hot rolling