Degrease unit

In the process of high temperature annealing,surface grease affect plating and black surface and adhesion caused by high temperature annealing

Category:

Keywords:

Degrease unit

In the process of high temperature annealing,surface grease affect plating and black surface and adhesion caused by high temperature annealing.Strip steel degreasing cleaning line is used to steel surface of electrolytic cleaning,remove the strip surface residual iron and other pollutants,make annealing steel plate surface carbon residue,to effectively control the residual amount of iron,and inhibits the annealing strip steel bonding defects,achieve tinplate,car plate,home appliance board cleanliness requirements.

Production process

Uncoiler-two roller pinch machine-five roller straightening machine-shearing machine-welding machine-two roller pinch machine-chemical degreasing-roll scrubbing of degreasing-electrolytic degreasing-water scrub-water spray cleaning-air dryer-shear machine-recoiling machine

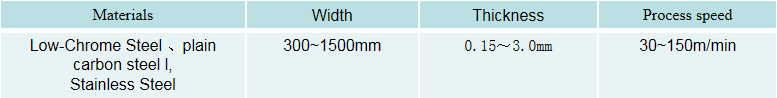

Technical parameter:

Previous page

Next page

Previous page

Temper mill unit

Next page

With the feature of good surface quality,good surface finish,high precision,excellent product property,etc.Cold Rolled strip is widely used for Continuous hot galvanizing line(CGL)

Continuous hot galvanizing line(CGL)

Continuous hot galvanizing line(CGL)continuous plate of zinc or aluminum zinc coating on the surface of cold-rolled steel plate,increase the corrosion resistance of steel plate

Color coating line(CCL)is to coat the strip surface with organic,make the surface more colorful and further enhance the corrosion resistance of strip

Pickling line plays a key role before cold rolling,Its main function is to use mechanical and chemical function,remove the strip iron and dirt of the strip steel surface after hot rolling