Chemical coater

Coating machine is indispensable equipment on galvanized,aluminum plating production line

Category:

Keywords:

Chemical coater

Chemical coater

Coating machine is indispensable equipment on galvanized,aluminum plating production line,used for galvanized sheet surface passivation solution and fingerprint resistant plating liquid.

Equipment composition

It consists of material roller,coating roller,bottom coating roller,coating roller,transmission device and batching system,etc.Glue roller and paint roller adopts the split type bearing seat,convenient maintenance and replacement.

Sticky material roller and coating roller adopt the independent variable frequency motor drive,can effectively control the thickness of the coating.

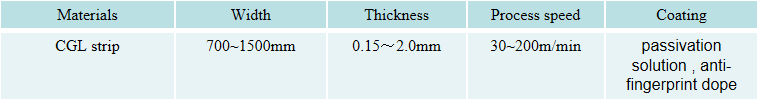

Technical parameter:

Previous page

Next page

Previous page

Continuous hot galvanizing line(CGL)

Next page

With the feature of good surface quality,good surface finish,high precision,excellent product property,etc.Cold Rolled strip is widely used for Continuous hot galvanizing line(CGL)

Continuous hot galvanizing line(CGL)

Continuous hot galvanizing line(CGL)continuous plate of zinc or aluminum zinc coating on the surface of cold-rolled steel plate,increase the corrosion resistance of steel plate

Color coating line(CCL)is to coat the strip surface with organic,make the surface more colorful and further enhance the corrosion resistance of strip

Pickling line plays a key role before cold rolling,Its main function is to use mechanical and chemical function,remove the strip iron and dirt of the strip steel surface after hot rolling