Continuous hot galvanizing line(CGL)

The shape and size error of raw materials,the condition of roller surface,roller bearing wear and equipment installation error factors

Category:

Keywords:

Continuous hot galvanizing line(CGL)

The shape and size error of raw materials,the condition of roller surface,roller bearing wear and equipment installation error factors,all can cause the uneven tension of steel strip width direction,so that the production should be equipped of multiple sets of error correcting device,make center line of the steel strip with the center line of the unit,in order to ensure the normal operation of the unit,finally get good products.

Our company can design the single roller rectification,double roller rectification,three roller rectification and two roll pinch correcting machine,in order to meet the different needs of the production line.

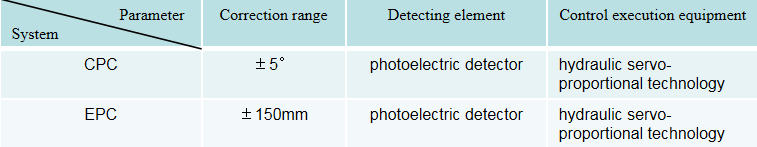

Technical parameter:

Previous page

Next page

Previous page

None

Next page

With the feature of good surface quality,good surface finish,high precision,excellent product property,etc.Cold Rolled strip is widely used for Continuous hot galvanizing line(CGL)

Continuous hot galvanizing line(CGL)

Continuous hot galvanizing line(CGL)continuous plate of zinc or aluminum zinc coating on the surface of cold-rolled steel plate,increase the corrosion resistance of steel plate

Color coating line(CCL)is to coat the strip surface with organic,make the surface more colorful and further enhance the corrosion resistance of strip

Pickling line plays a key role before cold rolling,Its main function is to use mechanical and chemical function,remove the strip iron and dirt of the strip steel surface after hot rolling